Network Cabling Problems caused by CCA and why you should avoid CCA.

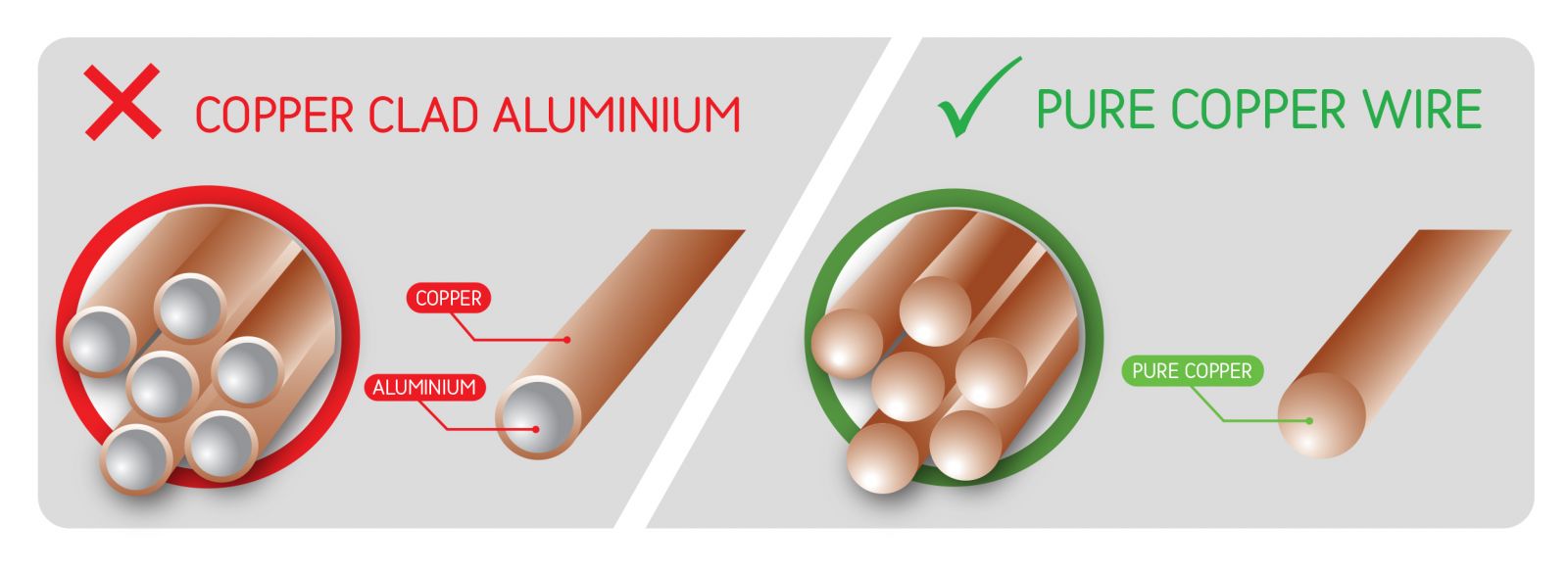

When network infrastructure budgets are tight, it can be tempting to cut corners where you can. One example of attempted cost savings is through Copper Clad Aluminum (CCA) cabling systems.

Offered as a cost-effective replacement for Pure Copper Cable, CCA cable is anything but an effective solution. While CCA products might look like (and be advertised to function like) standard Category 5e, Category 6 or 6a cabling, there are significant differences that could pose network problems, concerns about business continuity and safety hazards and these negative commercial implications will cost much more than the original savings gained.

Unfortunately, there is not one website we can point you to anywhere in the world from a standards viewpoint that will reference the use of CCA cables as Ethernet or Network cables. The Ethernet Network Standard IEEE802.3-2018 is written around the use of TIA/ISO Category or Class cable standards based on cables manufactured using Pure Copper Cable.

There are a variety of different cables available for Ethernet Networking applications. These network cables are described by their various categories, e.g., Cat 5 cables, Cat 6 cables, etc. which are recognised by International regulators including ISO and the TIA (Telecommunications Industries Association). These industry and regulatory bodies only approve and reference Pure Copper.

Several significant issues can arise when using CCA cabling systems as part of your network infrastructure.

Here, we outline a few of them for you.

UKCA CE Conformity: Even for Ethernet cable, many people think Ethernet somehow is not electrical in nature, either ultra-low voltage without PoE or low voltage when running PoE over it. All Category cables, whether they are 5e, 6 or 6a should be in packaging that carries the CE Mark as they comply with the Low Voltage Directive (LVD) and it is an obligation of the supplier to maintain a ‘Technical File’ of specification and test information for the product. When a product such as CCA cable is introduced to the market it cannot comply with this directive, and it does not comply with any standards, then the burden on the person placing the product on the market, or selling the product becomes more onerous to justify the conformity of their product to the essential safety requirements of the LVD.

Not approved to International Cabling Standards compliance: CCA twisted pair cables do not comply with either the US, UL, and TIA standards, European and International EN or ISO standards, which all call for Pure copper conductors.

Not Approved to International Applications Standards: CCA cable is not approved for use by IEEE802 Ethernet Standards due to poor data and PoE transmission characteristics and it can carry Ethernet data signals over distance (called attenuation). Attenuation is a fancy word for degradation in quality and, used in this context, the signal’s quality.

Installation issues with poor flexibility and bend radius: CCA cable is brittle and can easily break. It has been reported that even moving a patch cable in a patch panel or a faceplate can cause failures. It is important to note that the bend radius of CCA cabling is limited and is not tolerant of bends.

Conductors can break during termination: Due to low tensile strength, this reduced strength of the CCA conductor typically leads to poor retention of the wire within the Insulation Displacement Connector (IDC). IDC’s are used throughout the Network Industry and are designed for copper. Some CCA cables will snap off immediately or later fail, but always consequently offer poor termination reliability.

Oxidation and corrosion: CCA cables are very reactive. Aluminium oxidises when exposed to air and will cause low and high-frequency problems which may cause failed terminations in the network infrastructure, leading to connectivity problems. Network engineers can spend lots of time locating and addressing these failures.

PoE: The Power over Ethernet market share will be well over 40% by 2025. PoE technology enables the centralisation of power in one location. It provides high-speed connectivity to support the growing number of wireless devices in business, whilst eliminating the need to deploy separate power supplies. Powering this is also the development of standards to fuel the adoption of PoE solutions with gigabit connectivity, all designed to run on Pure Copper Network cables.

Not suitable for PoE applications and beware of cables overheating: PoE Category cables can now carry up to 90 Watts for IP phones, wireless access points and cameras. CCA cable is not suitable for PoE due to the higher resistance which can cause radiant heat to build up faster. In larger installations where many CCA cables are bundled together, the temperature rises generated and the increased resistance will compromise the supported cable length and potentially start a fire or damage a PoE device on the other end due to the inability to supply enough current. The higher DC resistance of CCA cable compared to Pure Copper introduces voltage drop, limiting the voltage available to the device which can also damage the device.

Finally, the applications perspective: Category cables, whether they are Category 5e, 6 or 6a, are built to standards which have been used since 1980, as the basis for transmission speeds that the IP world and Internet use through the IEEE Ethernet specifications. The original 802.3 Ethernet wire speeds started out at 100 MBps transfer rates, whilst we now have Gigabit Ethernet as a standard Network speed and support up to 40Gigabit Ethernet applications. This growth in Network speed to support the Internet, together with growth in the use of other applications such as IP video, IP Phones, IoT, Wireless Wifi6 & 5G and Power over Ethernet (PoE) places even greater demands on these copper cables. Perhaps the ever-increasing use of PoE equipment, within Ethernet networks, is the final application “killer” for CCA, as it just simply does not work with PoE equipment.

References